Industrial Load Pallet Storage Rack Shelf Panel Making Roll Forming Machine

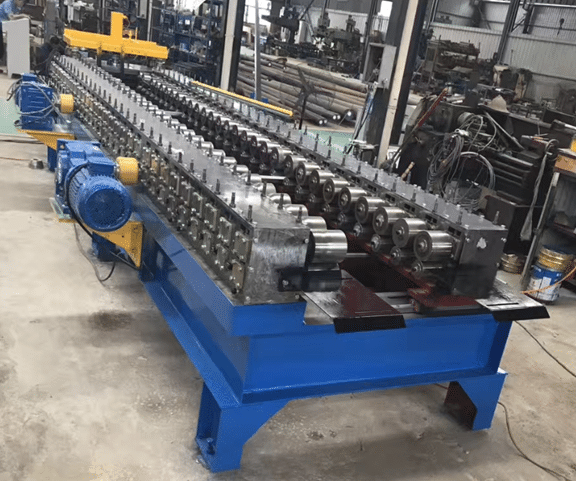

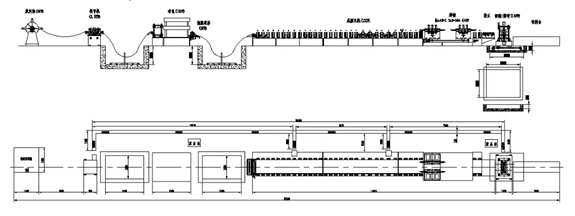

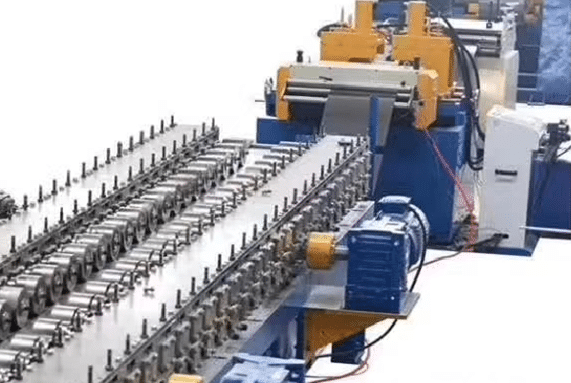

This kind of machine is consisted with auto decoiler, guide frame, lever/feeding section, continuous bottom hole punching section, forming section, positioning and cutting section, collection table and electrical control system etc.

Equipment Capacity

1. Equipment production capacity: width≤400mm, thickness of steel material: 1-2.5mm 2. Production speed: 8-15m/min

3.Total power: about 21.5kw

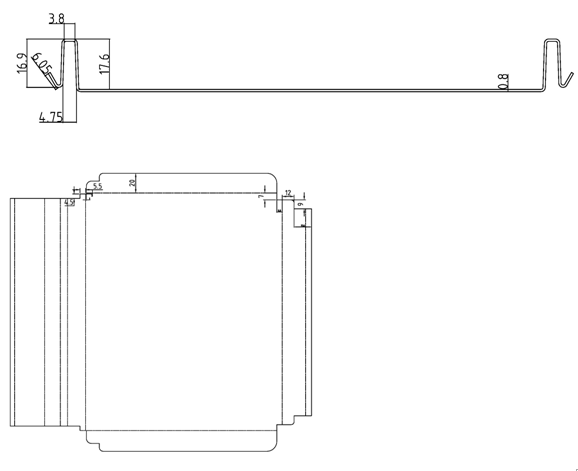

Take the following puplar Japanese Industrial Load Pallet Storage Rack Shelf Panel for example to show you how the machine is designed.

Main process parameters of the Industrial Load Pallet Storage Rack Shelf Panel Making Roll Forming Machine:

1. Maximum rolling thickness: 0.4-0.6 mm, using steel strip coil.

2. working speed: 0~6m/min

3. the total power of the unit: 7.5kw (power) 7.5kw (cut)

4. the total power of the whole machine: 20kw

5.the number of forming groups: about 20 groups

6. length accuracy: less than 1 meter: ± 0.5mm

The main components of the production line

Production process: discharging rack...opening machine...punching...servo feeding...rolling forming part...hydraulic cutting (or bending at the same time)

What make our Industrial Load Pallet Storage Rack Shelf Panel Making Roll Forming Machine different?

The main machine is 20 sets, cantilever structure, enclosed gear box, one side of the gear box is fixed type, the other side is sliding type (20 sets of overall servo movement), side plate hand movement telescopic 200-350, roll mold inner hole diameter 38mm, sliding adopts linear guide rail, and the inlet and outlet are provided with feeding guide and discharge guide.

(1) Drive motor: 7.5kw motor with 2 Mtk77 reducers.

(2) Roll material: GCr15.

(3) Rolling process: roughing - quenching - finishing - chrome plating, quenching hardness of 55-60.Inner hole and surface grinder are ground.

(4) Spindle material: 40Cr.

(5) Spindle process: quenching and tempering - lathe processing - fine grinding outer circle.

(6) The main machine adopts square tube welding and surface milling machine processing.

Hydraulic cut + hemming

Cutting + hemming is the last step of the unit, which can be cut and bent accurately at the required position under system control. The system consists of a hydraulic drive, a forming edge, a tool holder, and a hydraulic station. The machine bends once, and is positioned by the optical fiber and the encoder, and the bending is cut off in the stop state.

If you want to know more information about the rack making machine, please visit our other pages.

FAQ:

1.Does one Industrial Load Pallet Storage Rack Shelf Panel Making Roll Forming Machine can only produce one style product?

Not exactly. Our machines can produce more kinds of by change their rollers.

2. Do you have after sales support?

Yes, we are happy to give advice and we also send skilled technicians to your place to support the technical guidance. We will let your machines running that in order to keep your business running.

3. What can you do if the machine broken?

Our machine's warranty period is 12months. And if the broken parts can't be repaired, we will send the new one to replace the broken parts. And the only thing you need to do is paying the transport costs.

If beyond the warranty period, we can through the negotiation to solve the problems, and we will supply the technical support for the whole life of the machine.

Looking for ideal Industrial Load Pallet Storage Rack Shelf Panel Making Roll Forming Machine manufacturer & supplier ? We have a wide selection at great prices to help you get the target product. If you have any question, please contact us.

Looking for ideal Industrial Load Pallet Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the Storage Rack Shelf Panel are quality guaranteed. We are China Origin Factory of Roll Forming Production Line. If you have any question, please feel free to contact us.

Product Categories : Accessories Equipment

Mr. Cary xu

Mr. Cary xu