Brife introduction:

In the electrical wiring of buildings, a cable tray system is used to support insulated electric cables used for power distribution and communication. Cable trays are used as an alternative to open wiring or electrical conduit systems, and are commonly used for cable management in commercial and industrial construction. They are especially useful in situations where changes to a wiring system are anticipated, since new cables can be installed by laying them in the tray, instead of pulling them through a pipe. For zhongtuo cable tray Roll Forming Machine is a kind of machine for making cable tray by roll forming principle.

Cable tray system , there are many types. Here we only take one of them for exmaple.

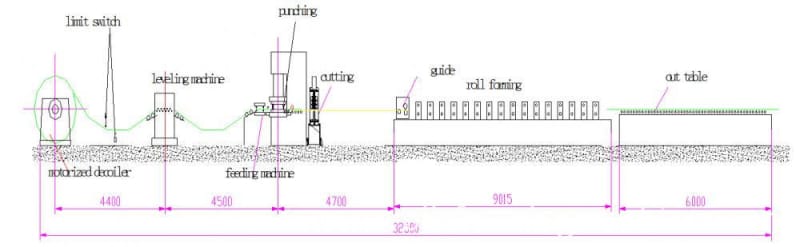

Working process of cable tray roll forming machine:

Auto-de-coiler-----leveling----servo feeding----hole punching----roll forming --re-coiler

Zhongtuo cable tray roll forming machine is composed by the following elements:

1 Auto-de-coiler 1

2 Leveling machine 1 5.5kw frequency change drive motor, speed adjustable

3 Support frame 3 Roller type

4 NC900servo feeder 1 NC900 Servo motor drive

5 Punching press 1 120ton

6 punching mould 9

7 Main forming machine 1 100-900mm,thickness 1-3mm,material of roller:GCr 15

8 Hydraulic cutting machine 1

9 Cutting blade 9

10 Run-out table 1

11 Electric panel 1 PLC control system

More detail information of cable tray roll forming machine:

de-coiler

Parameter: width of material: 225-1020mm thickness: 1-2mm;

Inner diameter of coil: φ508mm;inner expansion range: ф480-520 mm;

The maximal of Diameter: φ1500mm; The Maximal of loading: ≤5T

Motor power: 5.5kw frequency change control

Press material type: pneumatic press material

Feeding speed: 0-15m/min, adjustable

Leveling machine

A: working roller: nine rollers type leveling machine

B: Feature of structure: after the quenching and tempering, chrome-plating processing, the rigidity, surface roughness of the roller etc. are all enhance greatly; It is composed by the clamping roller and the leveling roller, the clamping roller may the independent control, the leveler has one pair of horizontal guide roller and two pairs of vertical guider roller and easy to adjust by hand wheel. Between the leveler and the feeding device, there is optical sensor, sends out the feedback signal to the control system, the control system sends out the instruction to the frequency conversion motor to change speed, Achieves the uninterrupted level goal.

servo feeding machine

A: function: material feeding

b. Feature: Uses the servo motor-driven .Multistage type feeding: May input 10 group of different feeding lengths. The liquid crystal touching screen demonstrated is advantageous for the change, establishes various technical parameters. The auto-induction start system and the punch press linkage (control punch press start).

Punching press

Model of punching press: JF21-120B

Punching press: Uses the steel plate welding fuselage, the rigidity is strong with good appearance .Uses the combined type air operated friction clutch.

Roll forming part

Forming station: 14sets

Forming variety: bridge frame

The maximal coil width: 1020mm

The maximal thickness:≤2.0mm

The diameter of the roller axis: ¢85mm

Roll mould material: Gcr15, quenching treatment: HRC58-62°

Drive type:22kw motor,ZQ500reducer motor

Hydraulic cutting

Cutting type: hydraulic cutting

Blade type: close type die cavity cutter

Hydraulic power:5.5kw

Material of blade: Cr12, quench treatment, hardness HRC56-58

Quantity: 9 (depend on customer request)

Run-out table

Structure: roller type with no power

Electric control system

A: Full line is controlled by PLC control system,touch screen operation to achieve the human and PLC interactive. The operator can monitor the setting program (programmable control) and modify the parameter to control the line. Also can check the running status, parameter and error indication etc..

B: Operation type: manual /auto two type switch. In manual position: can run the each part of the machine. In auto position: can run the full line. The emergency was stopped ensure the safe of the equipment and operator.

C: Machine side is equipped with the manual operation control panel for convenient worker to operate;

D: Entire line surveillance function: to reach surveillance production line movement condition, realizes to various locations production condition surveillance;

E: Has the failure detection function: Carries on to the production line signal succession examines, the checkup according to sequence, discovers the mistake, and giving the alarm to stop the machine.

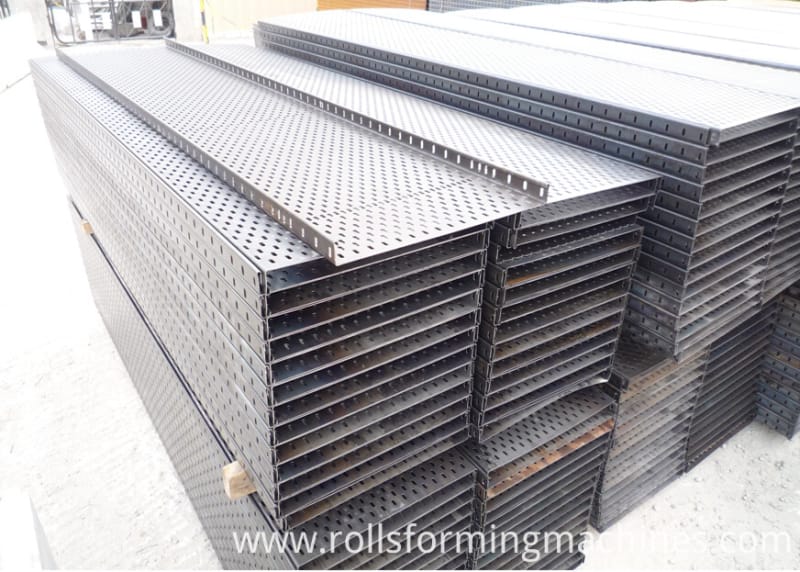

Cable tray made by Zhngtuo cable tray roll forming machine:

Looking for ideal Cable Tray Machine Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the

Cable Tray Making Machine are quality guaranteed. We are China Origin Factory of Cable Tray Roll Forming Machine. If you have any question, please feel free to contact us.

Product Categories : Cable Tray Roll Forming Machine

Mr. Cary xu

Mr. Cary xu