Ceiling Tee bar roll forming machine is also called light gauge steel framing machine.It is widely used in wall, floor and truss framing. Our light gauge steel framing machine produce studs & track from 3 5/8″(92.1mm) to 8″(203.2mm) widths with light gauge steel from 24(0.701mm) to 14(1.994mm)gauge.

For this Half automatic Ceiling Tee bar roll forming machine, you needs to punch hole on the Tee bar yourself. This half automatic version Tee bar roll forming machine only can change coil to T bar shape. If you need punching machine, we can make for you or you can buy from the market.

And we have full automatic ceiling Tee bar toll forming machine,for this machine,the roll forming ,punching the head and holes with make together, after cutting, it is a finished product.

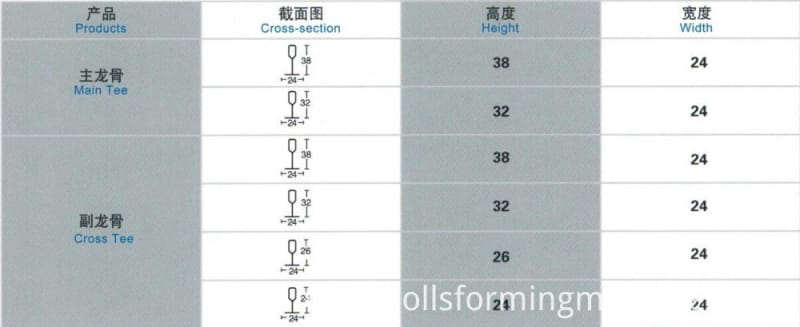

What types of ceiling Tee bar we have?

About the ceiling roll forming machine,we have many types, such as Tee bar machine, Tee bar with black line,C channel machine,U channel machine,Omega shape machine and so on.But the mainly used it Tee bar, there are some general size,30x24mm,32x24mm,26x24mm 38x24mm,32x15mm and so one.

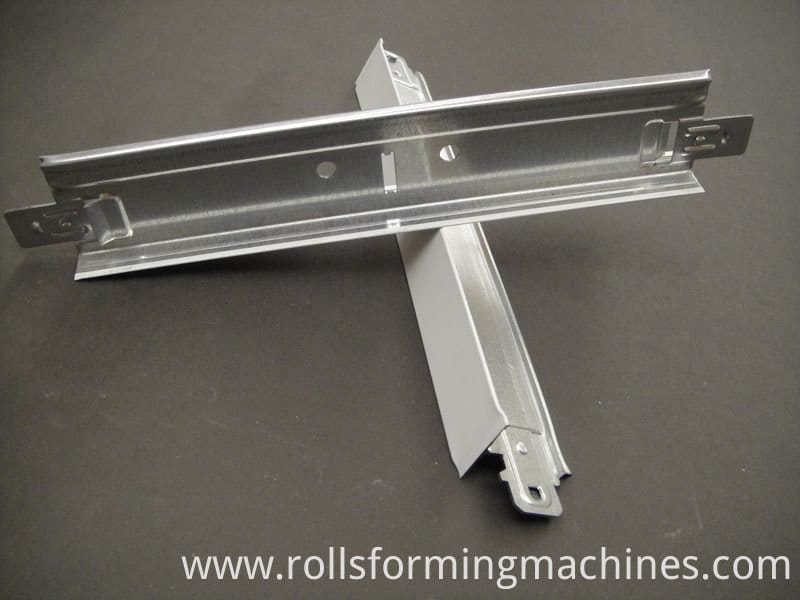

There are some profile drawing and final product of Tee bar for you reference.

basic parameters:

Raw material

Processing material: GI

Material thickness: 0.2-0.4mm

Material hardness: 550 MPA-350 MPA

Decoiler

Usage:Support two kinds of coils for automation

Loading capacity: 1.5T

Uncoiling width: 300mm

Inner diameter: 450-550mm

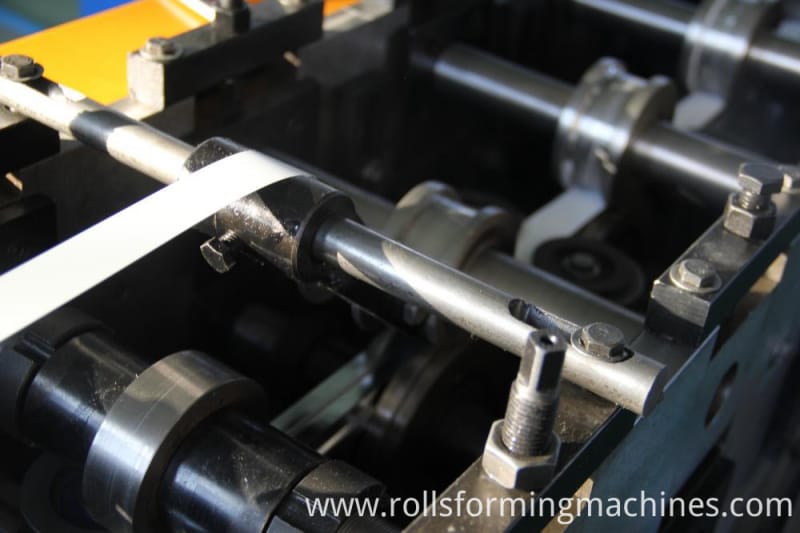

Main machine for Ceiling Tee bar machine

Size: 3500х800х1400mm

Weight : 3 tons

Voltage:380V/50HZ3Phase (as customer`s request)

Rollerfixer : Guide column

Frame:middle plate welded, memorial arch frame type

Frame thickness:25mm

Drive mode: gear box

Material rollers: GCr12MoV

Material of shafts: 45# steel with tempering

Diameter of shafts: φ40mm

Number of rollers : 16 rollers

Main power: 3kw

Cyclical planetary gear speed reducer)

Notice: different sizes will be produced by adjusting the spacers by hand.

Shearing Mechanism

Material of blades: Gcr12MoV quenched

Power: hydraulic power

Frame : Pillar style with rack & pinion system

Stroke switch : non-contact photoelectric switch

Components: It contains one set of cutting tools, one hydraulic tank and one cutter machine.

Payment method:

Payment of the contract with following schedule:

- 30%: The payment shall pay by T/T the down payment to the Seller within 15 days after the signature of the Contract. The Contract then comes into effect.

- 70%: The buyer shall pay to seller the remaining 70% of total contract amount before the seller`s ship the machine to XINGANG, CHINA.

Installation, Commissioning, Test and Training of Ceiling Tee bar roll forming machine

1. The engineers from the Seller shall supervise the installation on site and fulfill the commissioning. They should start off within 10 days after they get the information from the Buyer.

2. The Buyer signs in the Certificate of Acceptance.

3. The Seller trains the operators of the Buyer during the commissioning

4. Commissioning: about 1 engineers in 7 days.

5. The Buyer shall pay for the international air tickets and the local, such as board and lodging, daily transportation, communication,Insurance, etc. The Buyer shall pay USD 100 /day /person to the Seller for the commissioning.

6. The Buyer shall prepare an interpreter for better communication between the two sides.

Looking for ideal Tee Bar Roll Forming Machine Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the Ceiling Tee Machine are quality guaranteed. We are China Origin Factory of Ceiling Tee Bar Machine. If you have any question, please feel free to contact us.

Product Categories : C/U/ Channel & T Bar Roll Forming Machine > Ceiling Channel Roll Forming Machine

Mr. Cary xu

Mr. Cary xu