Features

1. The corrugated panel roll forming machine can produce corrugated sheets with different thicknesses.

2. The corrugated panel roll forming machine can work at 40m/min. The normal speed is 16-20m/min.

3. The material thickness can be from 0.2mm to 4.0-5.0mm , according to your requirement.

Application

The products of the corrugated panel roll forming machine are used as roofing and wall sheets for factories, warehouses, garages, exhibition centers, cinemas, gardens, etc.

Parts of Roof Roll Forming Machine:

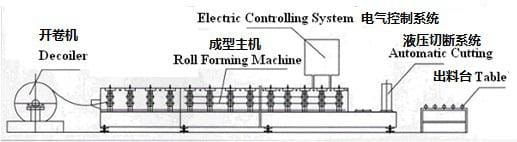

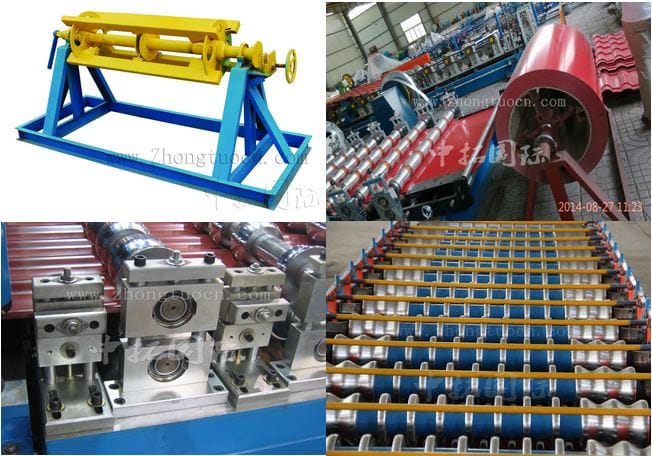

Components of corrugated roll forming machine production line

1. Manual Decoiler: set 1

2. Punching part: set 1

3. Main forming machine: set 1

4. PLC control sysem: set 1

5 . Hydraulic pump station: set 1

6. Post cut: set 1

7. Electric motor: set 1

8. Output table: set 1

Equipment Maintenance

Meticulous daily maintenance is essential to elongating the corrugated panel roll forming machine's service time. The following steps need to be part of the machine's daily production and usage routine.

1. Regularly lubricate the outside parts of the corrugated panel roll forming machine, i.e., driving chain, etc.

2. Regularly wipe the surface of roller, particularly in case of outside working. If its downtime is long, you should daub lube on the roller surface. Make sure to clean it the next time you use it.

3. If the corrugated panel roll forming machine will not be used for a long time, cover it with plastic or cloth to avoid rain on the machine or the machine becoming damp, especially the electric control box.

4. Make sure the cutting system is lubricated when necessary.

5. Check the hydraulic station often and the oil quantity of the deceleration machines. Add more oil if the oil level is low.

6. Check the electric appliances box and every leads conjunction circumstance of the corrugated panel roll forming machine. Dust the machine often.

ZTRFM has been dedicating to roll forming technologies for over 2 decades and now boasts strong experience, capabilities, innovative thinking and roll forming expertise to provide perfect roll forming solutions to our clients. At ZTRFM, we can help build a better future for you and your customer.

FAQ

1. IS AFTER SALES SERVICE AVAILABLE?

Yes, we offer 7x 24hours online support and our engineers can work oversea to help.

2. HOW CAN I GET TO YOUR FACTORY?

a. First fly to Beijing airport and then go from Beijing Nan to Cangzhou Xi (1 hour) by high speed train . Then we can pick you up at the railway station.

b. First fly to Shanghai Airport and then go from Shanghai Hongqiao to Cangzhou Xi(4.5 hours) by high speed train. Then we can pick you up at the railway station.

3. WHAT IF SOME PARTS BREAK?

We offer warranty of 12 months ,during which free spare parts are available if some parts of the machine break to be irreparable. Besides, we also offer whole life technical support which means we will still offer technical advice 1 year after your purchasing. We can discuss to help you out.

4. CAN YOU TAKE CHARGE OF TRANSPORT?

Yes, we have strong expertise in this area for years and you can trust us.

Looking for ideal Colorful Panel Forming Machine Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the Colorful

Steel Roll Forming Machine are quality guaranteed. We are China Origin Factory of New Corrugated Roll Forming Machine. If you have any question, please feel free to contact us.

Product Categories : Roofing Sheet Roll Forming Machine > Corrugated Roof Roll Forming Machine

Mr. Cary xu

Mr. Cary xu