1010 tile water ripper glazed step tile steel making Roll Forming Machine

1010 tile water ripper glazed step tile steel making roll forming machine is used to make the step tile in batch fully automatically. And this step tile is quite popular in European.

Compared with the tradtional glazed Tile Making Machine, this one the speed is faster and it is more stonger than the normal roofing sheet machine.

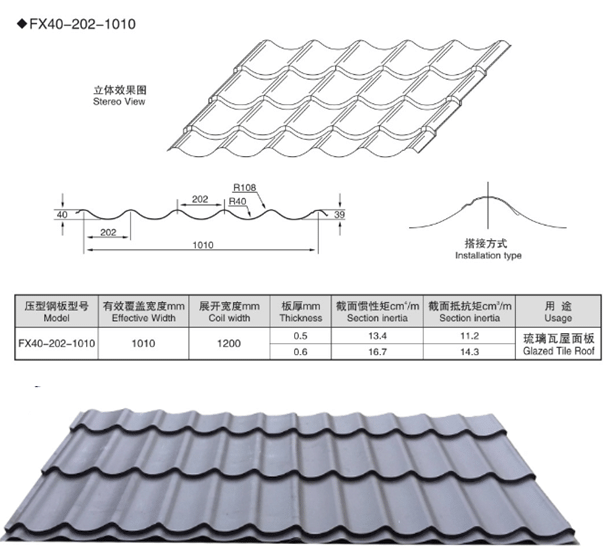

Take the 1100 tile water ripper glazed step tile drawing profile for your reference:

Based on the 1010 tile water ripper glazed step tile, we design the machine like following:

1010 tile water ripper glazed step tile steel making roll forming machine parameters for your reference:

Manual uncoiler-- roll forming machine-- PLC control box-- hydraulic cutter- receiving table

| Part details | Item Name | Specification |

| Manual uncoiler | carrying capacity | 6 tons |

| Stype | Manual |

| Raw coil | Coil material | steel |

| Coil thickness | 0.3-0.8 mm |

| Machine body | Roller station | 17 station |

| Roller material | Gcr15 quencing at 58 degree |

| Shaft material | Gcr15 quencing at 58 degree |

| Shaft diameter | 90 mm |

| Machine weight | About 6.5 tons |

| Machine size | 7.5*1.5*1.5 m |

| Speed | 5-8 m/min |

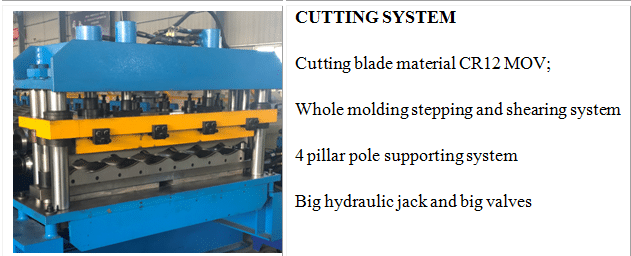

| Cutter | Operate | Hydraulic cutting |

| Blade material | Cr12 |

| Power | Operate | Chain transmission |

| Chain size | 1 inch chain |

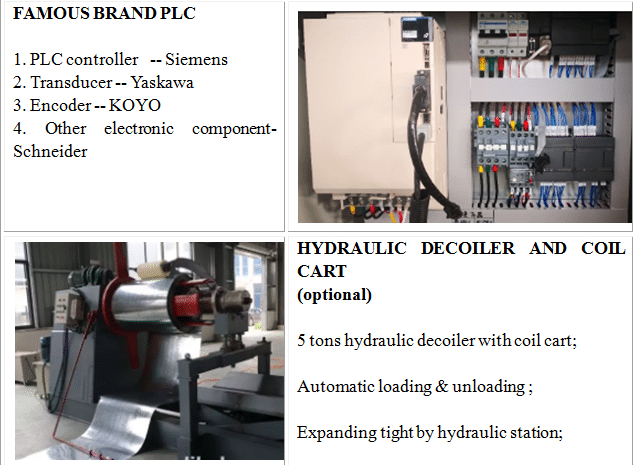

| Control system | PLC brand | Taiwan delta |

| Motor power | 7.5 kw |

| Hydraulic pump power | 4 kw |

| Voltage | 380V 50Hz 3phase |

| Machine color | As ur need |

| Machine language | Chinese and English |

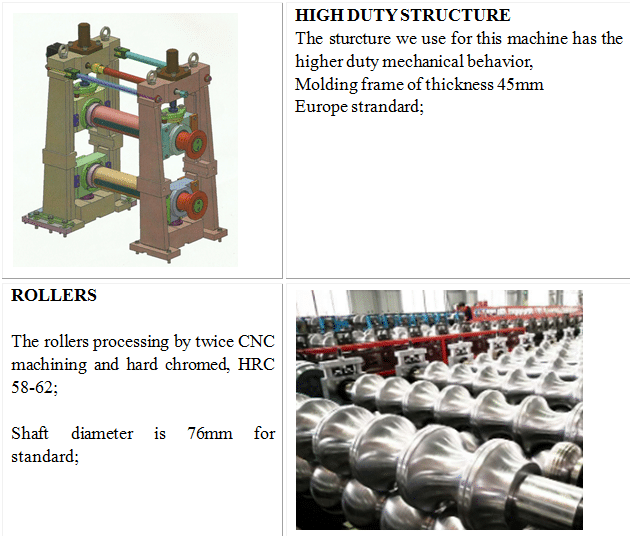

Why this glazed step tile steel making roll forming machine can reach high speed?

1.We use the molding frame of 45mm, to make sure when machine working high speed, it can also working long time.

2.The transmission it uses gearbox to make sure the power given evenly and smoothly.

3.The hydraulic power is big enough to make do the fast stepping and shearing.

4.As to the machine it has electricity accumulator to make sure the non-stop working.

5.The shearing and stepping, we use the whole molding design, by this way, the step and shearing can do at the same time to reduce the working time.

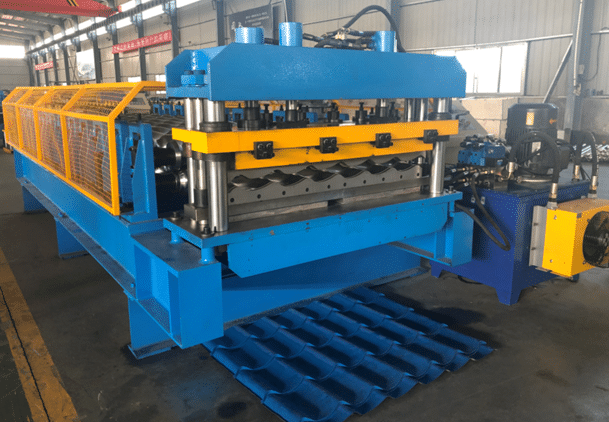

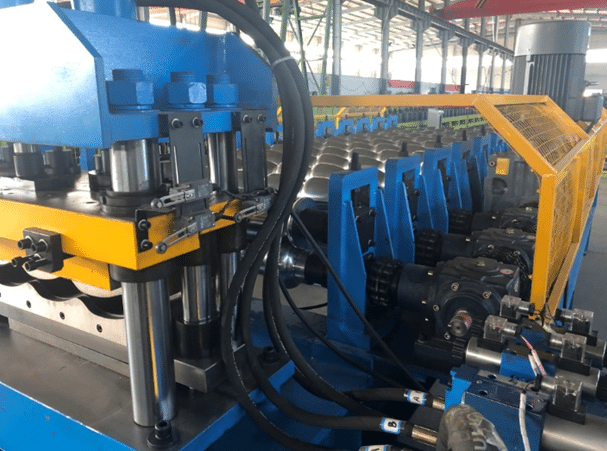

Here are more pictures for your reference:

FAQ:

1.Does one 1010 tile water ripper glazed step tile steel making roll forming machine can only produce one style product?

Not exactly. Our machines can produce more kinds of by change their rollers.

2. Do you have after sales support?

Yes, we are happy to give advice and we also send skilled technicians to your place to support the technical guidance. We will let your machines running that in order to keep your business running.

3. What can you do if the machine broken?

Our machine's warranty period is 12months. And if the broken parts can't be repaired, we will send the new one to replace the broken parts. And the only thing you need to do is paying the transport costs.

If beyond the warranty period, we can through the negotiation to solve the problems, and we will supply the technical support for the whole life of the machine.

Looking for ideal 1010 tile water ripper glazed step tile steel making roll forming machine manufacturer & supplier ? We have a wide selection at great prices to help you get the target product. If you have any question, please contact us.

Looking for ideal Water Ripper Machine Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the Step Tile Making are quality guaranteed. We are China Origin Factory of 1010 Glazed Step. If you have any question, please feel free to contact us.

Product Categories : Roofing Sheet Roll Forming Machine > Glazed Tile and Ridge Cap Roll Forming

Mr. Cary xu

Mr. Cary xu