Sandwich Roof Panel is a new wall materials which is good for insulation, heat insulation,sound insulation fire-retardant, waterproof, lightweight.It is widely used in high-rise office buildings and high walls enclosing and decorative, industrial plants, cold storage, clean rooms and insulation containers, etc.

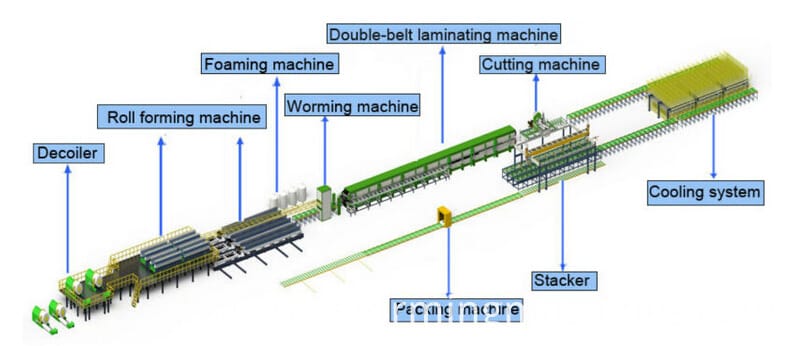

This Sandwich Roof Panel Roll Forming machine include De-oiler,Laminating machine,roll forming system,forming machine,foaming part,Double-belt lamination machine,cutting part,cooling system,stack,packing machine.

Decoiler--- Laminating machine(cutting)---Roll forming machine---Worming machine--- Foaming machine---Double-belt laminating machine---Cutting part---Cooling system---stack and packing

Cutting length:Min 3m, max 15mm

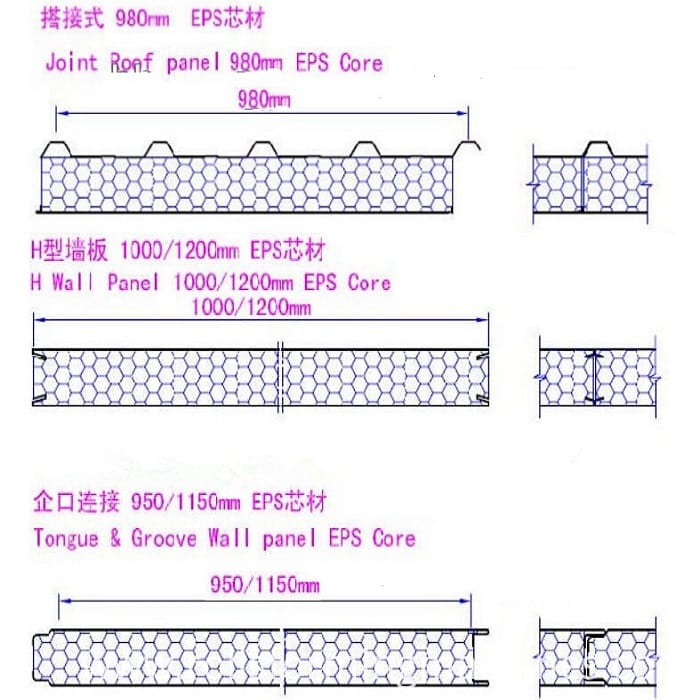

PU sandwich panel width:800-1150mm(design by customer)

PU sandwich panel thickness:50-100mm

PU foam materials:Polyether and isocyanates

PU foam density:30-45kg/m3

Max width of coil:1250mm

Max weight of coil:10T

Diameter of coil:508-610

The thickness of coil:0.5-0.8mm

Hardness:235MPa

speed:5-8m/min

The length of production line:80m

Working height:1200mm

Foam casting working pressure:150-200 bar

the effective length of Double-belt:24mm

Control system:Imported PLC

Total power:90KW

Voltage:380V/50HZ

Control voltage:24V/110V220V

Air pressure:0.7Mpa

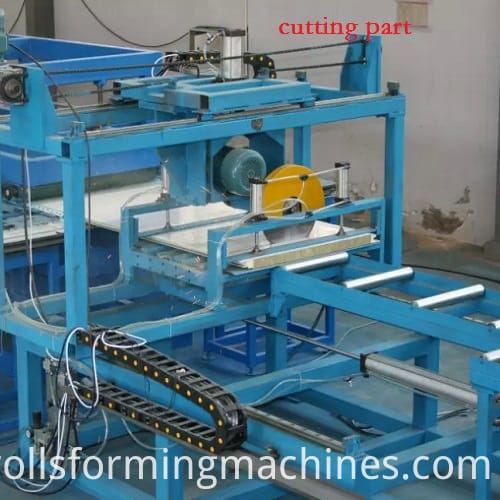

Details of andwich Roof Roll Forming Machine :

Looking for ideal Sandwich Panel Machine Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the Roof Panel Roll Forming Machine are quality guaranteed. We are China Origin Factory of Sandwich Roof Roll Forming Machine. If you have any question, please feel free to contact us.

Product Categories : Sandwich Panel Roll Forming Machine

Mr. Cary xu

Mr. Cary xu