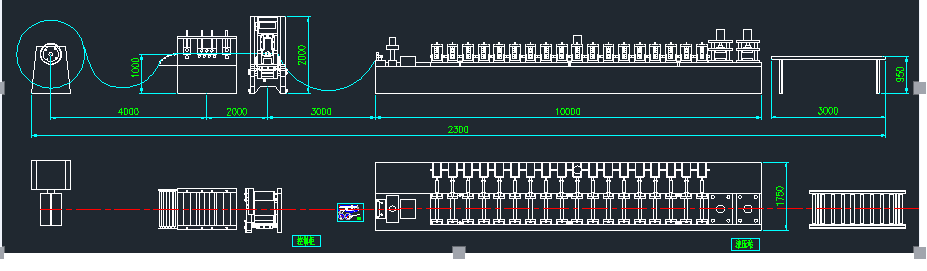

| No. | Name | Type | QTY | Power(KW) | Mark |

| 1 | Decoiler | 5THydraulic decoiler | 1set | | |

| 2 | Servo feeding &leveling | with independent control device | 1set | 7.5KW | Pneumatic |

| 3 | Punch machine | Yangli 80TONS | 1SET | | |

| 4 | Punch dies | | 1SET | SKD11 | design as holes |

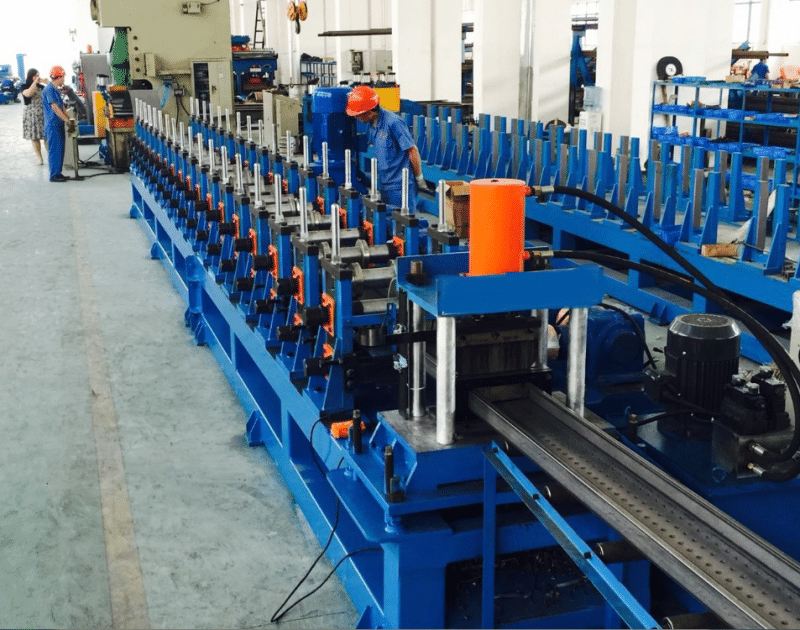

| 5 | Main forming machine | memorial arch type,gear box drive | 1SET | 22KW | |

| 6 | pneumatic circuit | 0.5m2/min;0.7Mpa | 1SET | | |

| 8 | Hydraulic cutting | | 1SET | 5.5KW | |

| 9 | Control system | PLC CONTROL | 1SET | | |

| 10 | Runout table | 3M | 1SET | | |

Metal Scaffolding Plank/Catwalk Roll Forming Machine Work Flow:

Metal Scaffolding Plank/Catwalk Roll Forming Machine parts:

1. 5ton Hydraulic Decoiler

Hydraulic tightening, built-in motor drag.

Ø Bearing capacity: <5t

Ø Applicable material roll inner diameter: φ508mm

2. Metal Scaffolding Plank/Catwalk Roll Forming Machine Punch Machine

Adopt more advanced straight punching method to improve punching efficiency.

When the plate thickness changes, first adjust the center distance between the upper and lower rollers of the roller punch roller, and then adjust the bridge gear through the adjustment device.

3. Metal Scaffolding Plank/Catwalk Roll Forming Machine Punch Machine Main Forming Machine

Supported coil width: ≤500 mm

Material thickness: 1.2mm-2.0 mm

Supported mateiral: S275 GI

Machine working speed: 5~10 m/min

Main power: 22kw

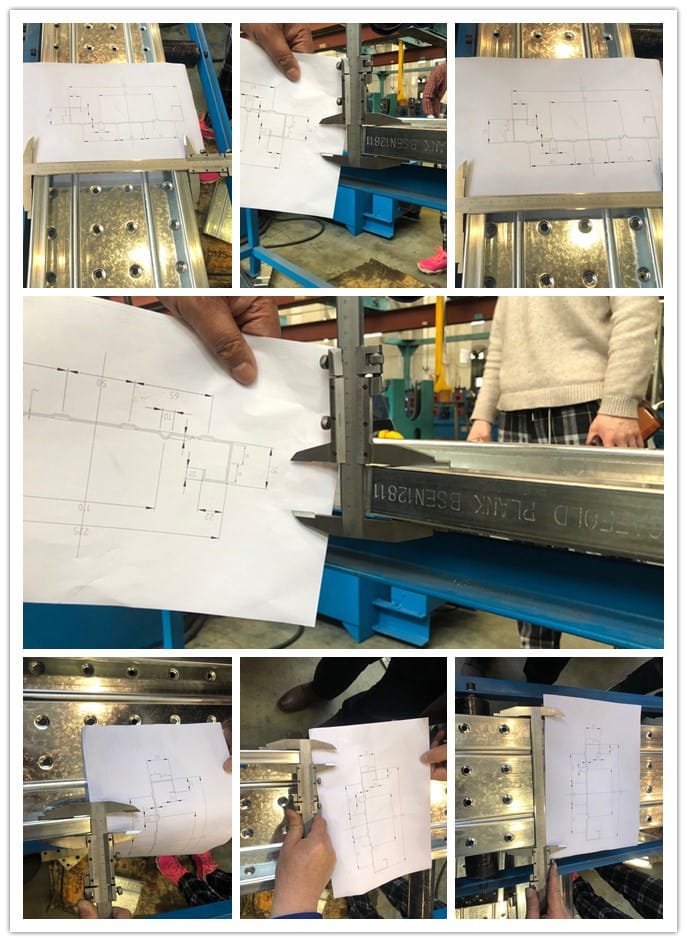

Check about our precision:

Our Services

1. Installation and training:

a.If buyers visit our factory and check the machine, we will teach you how to install and use the machine, and also train your workers/technician face to face.

b.Without visiting, we will send you user manual and video to teach you to install and operate.

C.If buyer needs our technician to go to your local factory, please arrange board and lodging and other necessary things.

2. After Service

a.One year guarantee for whole machine.

b.24 hours technical support by email or calling

c.If there is any problem found of the machine, we will repair it for free in one year.

Company Information

ZTRFM has been dedicating to roll forming technologies for over 2 decades and now boasts strong experience, capabilities, innovative thinking and roll forming expertise to provide perfect roll forming solutions to our clients. At ZTRFM, we can help build a better future for you and your customer.

FAQ

1. IS AFTER SALES SERVICE AVAILABLE?

Yes, we offer 7x 24hours online support and our engineers can work oversea to help.

2. HOW CAN I GET TO YOUR FACTORY?

a. First fly to Beijing airport and then go from Beijing Nan to Cangzhou Xi (1 hour) by high speed train . Then we can pick you up at the railway station.

b. First fly to Shanghai Airport and then go from Shanghai Hongqiao to Cangzhou Xi(4.5 hours) by high speed train. Then we can pick you up at the railway station.

3. WHAT IF SOME PARTS BREAK?

We offer warranty of 12 months ,during which free spare parts are available if some parts of the machine break to be irreparable. Besides, we also offer whole life technical support which means we will still offer technical advice 1 year after your purchasing. We can discuss to help you out.

4. CAN YOU TAKE CHARGE OF TRANSPORT?

Yes, we have strong expertise in this area for years and you can trust us.

Looking for ideal Scaffold Plank Making Machine Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the Catwalk Roll Forming Machine are quality guaranteed. We are China Origin Factory of Scaffold Board Roll Form Machine. If you have any question, please feel free to contact us.

Mr. Cary xu

Mr. Cary xu