Upright Sigma Profile For Warehouse Making Machine

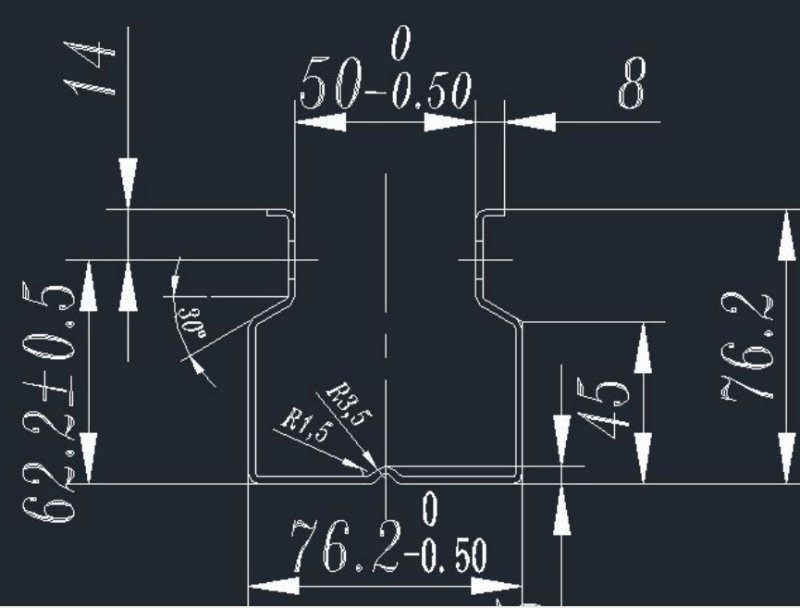

Upright sigma profile now it is quite popular for making pillar of upright or support, normally there are heavy duty type. Normally speaking, it is used together with the beam box. The material thickness is normally from 1.5 to 3.5 mm. The following drawing profile is for your reference.

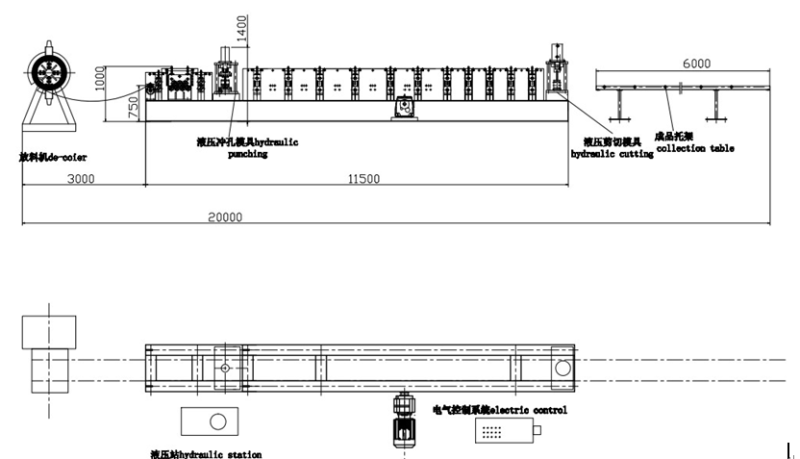

Here is the Upright Racking Roll Forming Machine working process for your reference:

Hydraulic De-coiling---Material guiding---Levelin---Hydraulic punching---Roll forming---Length sizing---Cutting the panel---Panels to the collecting platform---Finish

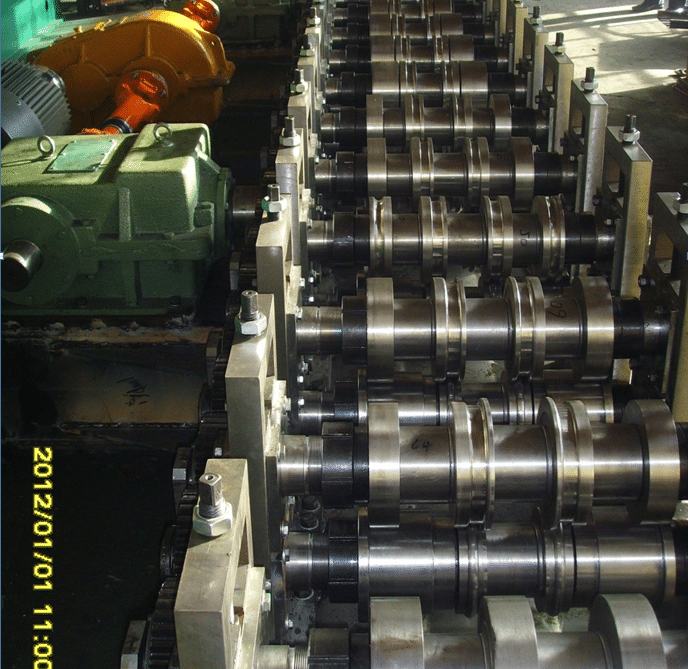

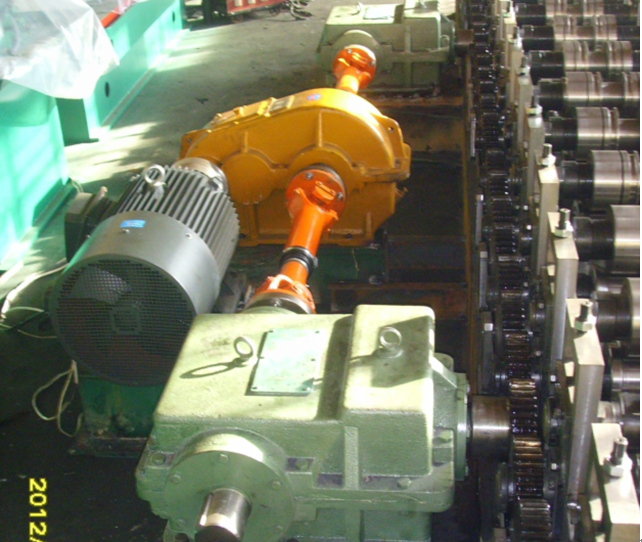

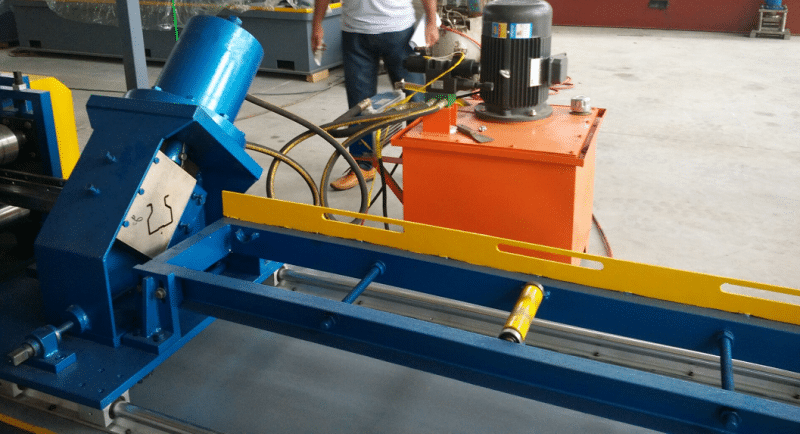

Main composition of the upright pillar Storage Rack Roll Forming Machine The machinery line consists of 5.0 tons hydraulic de-coiler , material guiding , leveling , hydraulic punching , forming roller system, hydraulic cutting system ,run-out table, control cabinet with PLC. Technical parameters: • Matching material: G.I or M.S • Material thickness range:1.2-1.8mm • Main motor power: 15kw • Forming speed:1-3m/min(include punching and cutting time) • hydraulic station power:22kw • Quantity of stands:about 16 • Shaft Material and diameter:¢75mm, material is 40CR • Material Of The Stations: Guide rail style • Tolerance:3m+-1.5mm • Way Of Drive:1.5 inch single chain • Controlling system:PLC • Total weight:about 8 Tons • Voltage: 380V/ 3phase/ 50 Hz • Size of the machine:L*W*H 11.5m*1.5m*1.2m • Material of forming rollers:Gcr 15, coated with chromed treatment • Material of cutter blade:Cr 12 mould steel with quenched treatment 58-62 Cutting and the Control Cabinet

Cutting of upright pillar Racking Frame Roll Forming Machine: 1) Cutting motion: The main machine automatically stops and then cutting. After the cutting, the main machine will automatically start. 2) Material of blade: GCR12with heat treatment 3) Length measuring: Automatic length measuring 4) Tolerance of length: +/- 1.5mm  Control Box: Brand Panasonic 1) Voltage, Frequency, Phase: 380 V, 50 Hz, 3Phase (this is can depend on customer request) 2) Automatic length measurement: 3) Automatic quantity measurement 4) Computer used to control length & quantity. Machine will automatically cut to length and stop when required quantity is achieved 5) Length inaccuracy can be amended easily 6) Control panel: Button-type switch and touch screen

Control Box: Brand Panasonic 1) Voltage, Frequency, Phase: 380 V, 50 Hz, 3Phase (this is can depend on customer request) 2) Automatic length measurement: 3) Automatic quantity measurement 4) Computer used to control length & quantity. Machine will automatically cut to length and stop when required quantity is achieved 5) Length inaccuracy can be amended easily 6) Control panel: Button-type switch and touch screen 7) Unit of length: millimeter (switched on the control panel)

Packing List details 1) 5 ton hydraulic de-coiler: 1 set 2) Main Roll Forming Machine:1 set 3) Hydraulic punching system: 1 set 4) Hydraulic cutting system: 1 set 5) Hydraulic station: 1 set 6) Control box: 1 set 7) Hydraulic cutting: 1 set 8) Run-out table: 1 set 9) Punching mould: 1 set 10) Cutting mould: 1 set Here are some finished product pictures for your reference:

Looking for ideal Upright Sigma Making Machine Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the Sigma Making Machine are quality guaranteed. We are China Origin Factory of Ware House Pillar Making Machine. If you have any question, please feel free to contact us.

Product Categories : Racking Roll Forming Machine

Mr. Cary xu

Mr. Cary xu